Environmental Monitoring

At DALPL our Sampling programs include the collection of samples during production on a regular basis from work surfaces in a randomised manner which will reflect the differing working conditions. In addition, DALPL collects samples from these sites after sanitising and from sites which may serve as harbours of resident organisms.

Sampling should not only be conducted on contact surfaces, but the evaluation of non- contact surfaces such as conveyor belts, rollers, walls, drains and air is equally as important as there are many ways (aerosols and human intervention) in which microorganisms can migrate from non contact surfaces to food & pharma products.

DALPL helps the client establish & accomplish a robust sampling program to avoid contamination

Environmental Monitoring Services

Selection of Sampling sites for monitoring

Protocol Development / Sampling programme development

Trend Analysis & establishment of alert and action levels

Establish rational for cleaning process, types of disinfectant used and its rotation period and frequency of cleaning

Conducts regular reviews of monitored data as the basis of assessing compliance with defined criteria

Assess and interpret all environmental monitoring data to ascertain wheter environmental control measures and practices are functioning.

Formal & informal Site visits to assess the facility environment

Training to staff at the facility

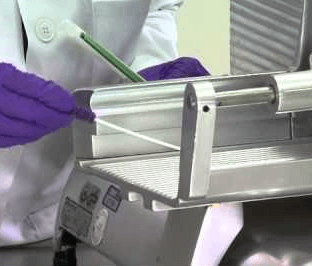

Swab Tests

Plate exposure to air